In recent years we have seen a rash of equipment in need of fuel system overhauls due to old gas causing a residue build-up preventing proper fuel flow. Ethanol is the main culprit in most of these cases. It attracts water within the gasoline and this combination can cause the ethanol to drop out of suspension, leaving the residual gas to gum up the fuel components. Additionally, when the ethanol has been in the equipment for an extended period of time it can cause deterioration of the interior components.

We recommend that customers purchase gas no more than a week prior to use and only plan to store it for three weeks. Any longer than that runs a greater risk of moisture entering the fuel supply and reacting as described above. When finished using the equipment for the season purchase ethanol-free gasoline (we sell quarts of it, as do most hardware stores) and run that through your fuel system until the machine stops. This way the only fuel left in the fuel system for storage does not contain potentially-damaging ethanol.

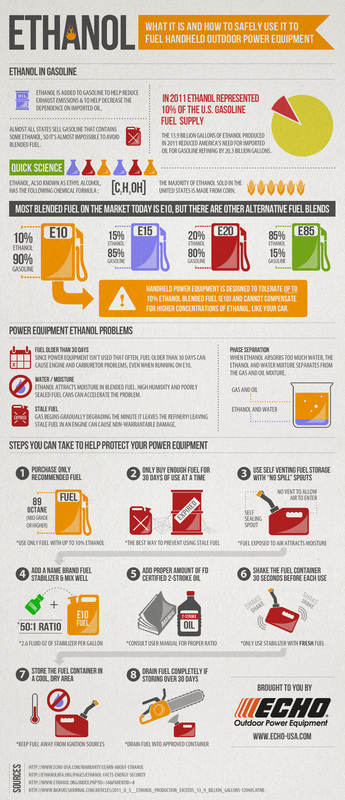

Here is an infographic produced by Echo Incorporated a couple of years ago. It does a fantastic job of explaining ethanol.

We recommend that customers purchase gas no more than a week prior to use and only plan to store it for three weeks. Any longer than that runs a greater risk of moisture entering the fuel supply and reacting as described above. When finished using the equipment for the season purchase ethanol-free gasoline (we sell quarts of it, as do most hardware stores) and run that through your fuel system until the machine stops. This way the only fuel left in the fuel system for storage does not contain potentially-damaging ethanol.

Here is an infographic produced by Echo Incorporated a couple of years ago. It does a fantastic job of explaining ethanol.

RSS Feed

RSS Feed